Welcome to SPI Industries

SPI Industries is part of the SPI Group. The Group is engaged in manufacturing of Transformer Cores, Transformer Radiators and Steel Drums. Based in Ahmedabad, it has a state-of-the-art manufacturing facility that manufactures world-class products. The company is ISO 9001 certified.

SPI Drums and Barrels are manufactured in accordance with international standards. They have long life and can be used to store any type of material.

SPI Steel Barrels

SPI Composite Barrels have a double shell protection. The inner side is a blow moulded HMHDPE barrel made from virgin high density polyethylene.

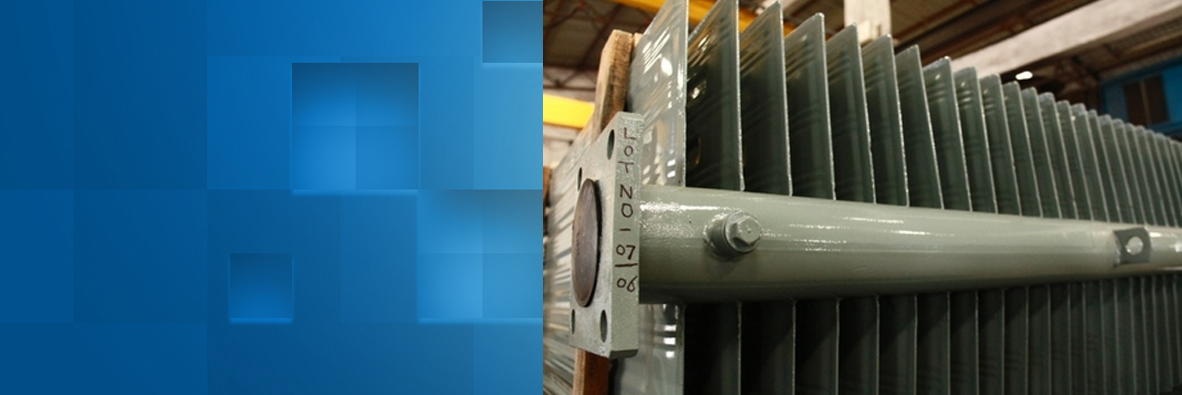

SPI Transformer Radiator

The standard radiators are blast-cleaned and given two coat each of Red Oxide Zinc Chrome primer and Enamel finish paint.